Niobium (Atomic number 41), is a greyish-silvery metal. It is a transition metal found in group 5 & period 5 on the periodic table. A fairly dense & ductile element, Niobium is similar to tantalum and found just above it on the periodic table. In fact, both niobium and tantalum are found together in the mineral columbite. Thanks to an oxide layer that forms on its surface, Niobium is very resistant to corrosion. And like tantalum, it is inert to bodily fluids. Due to its unique attributes, Niobium is the refractory metal of choice for a wide variety of interesting applications.

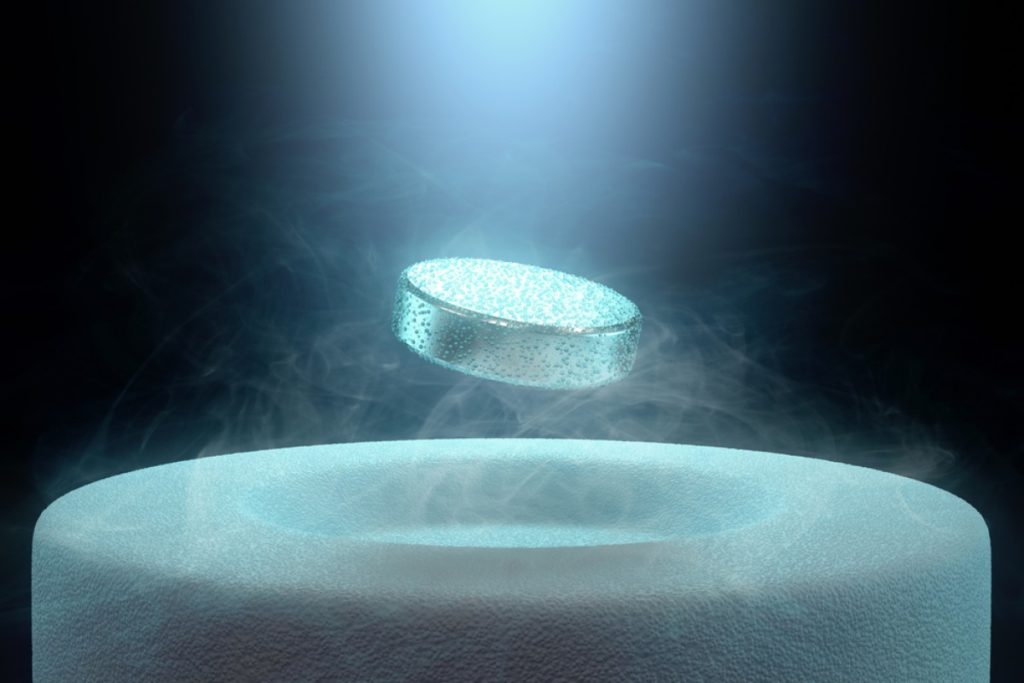

Superconductors:

Niobium is a superconductor. It boasts the largest magnetic penetration depth of all the known elements. Alloyed with titanium, the Niobium-Titanium alloy is superconducting at temperatures below ten Kelvin and can be found in superconducting magnets in hospital MRI equipment & several large superconducting magnets (the Tevatron accelerator at Fermilab & the large Hadron Collider).

Medical Diagnostic Equipment:

Niobium is found in the superconducting magnets used in Magnetic Resonance Imaging (MRI) scanners and Nuclear Magnetic Resonance (NMR) medical diagnostic equipment.

Oil & Gas Pipelines:

In amounts as low as 0.1 per cent, Niobium increases the strength of the resulting alloys, particularly at low temperatures. It also improves the alloy’s corrosion resistance, making it an ideal candidate for use in oil rigs and oil & gas pipelines.

Jewelry & Coinage:

Niobium is light weight, very malleable and similar to platinum in appearance. It is inert, hypoallergenic & scratch resistant. Anodizing Niobium creates a thin oxide layer that creates a range of permanent colors by diffraction of light. By varying voltages during the anodizing process, different layers of oxides are formed, resulting in a unique rainbow of iridescent colors. The jewelry industry offers rings, bracelets, necklaces and chainmaille jewelry designs created from Niobium. Austria has produced a series of silver-niobium euro coins with a niobium center colored blue, green, brown, purple, violet or yellow.

Aerospace & Military Industry:

Alloyed with other metals, the resulting high temperature-stable superalloys are used in jet engine afterburner liners, as burst disks for wind tunnels, reaction control nozzles for missiles and control nozzles for satellites. The niobium alloy also resists high frequency vibrations at cryogenic temperatures, which occurs in many satellite applications.

Optical Glass Production:

Niobium oxide is one of the raw materials used in lanthanum borate glasses. Lanthanum borate glasses are optical glasses having a high refractive index and a relatively low value of optical dispersion. The Niobium oxide compounds increase the refractive index of the glass and allow for corrective glasses to be made with thinner lenses.

Commercially Available Niobium Types:

The refractory metals industry offers several types of Niobium:

- Pure Niobium (commercially pure, min. 99.95%)

- Niobium-1% Zr: regarded as a low-strength alloy.

- C-103 (89% Nb, 10% Hf,1% Ti): regarded as a medium-strength alloy.

- C-129Y (10% W, 10% Hf, 0.1% Y): regarded as a high-strength alloy.

- Cb-752 (10% W, 2.5% Zr): regarded as a high-strength alloy.

Scientific Information for Pure Niobium:

Atomic Weight: 92.9064

Density: 8.57 g/CC

Melting Point: 2750 K, 2468°C, 4490°F

Boiling Point: 5017 K, 4927°C, 8571°F

Coefficient of Thermal Expansion: (20°C) 7.1 x 10-6/°C

Electrical Resistivity: (20°C) 15 microhms-cm

Electrical Conductivity: 13.2% IACS

Specific Heat: .126 cal/g/°C

Thermal Conductivity: .523 cal/cm2/cm°C/sec

Crystal Structure: bcc

Thermal Neutron Cross Section: 1.1 b

About Rembar Co. LLC

In business since 1950, Rembar is a stocking distributor and fabricator of Niobium. We stock niobium rod, wire, sheet, plate & tubing. We also precision-machine & form niobium to customer specifications. Visit us at www.rembar.com or call one of our knowledgeable sales engineers at 914-693-2620.