Tungsten Stock

Stock Supplies

These sizes are in stock, subject to prior sale. We also supply other sizes and alloys as well. See additional material information below.

Size to Weight Calculatorsheet

- .001″ x 12″ Coil

- .002″ x 12″ Coil

- .003″ x 12″ x Coil

- .005″ x 12″ x 36″

- .005″ x 24″ x Coil

- .010″ x 24″ x Coil

- .015″ x 24″ x Coil

- .020″ x 24″ x Coil

- .025″ x 24″ x R/L

- .030″ x 24″ x R/L

- .040″ x 24″ x R/L

- .060″ x 24″ x R/L

- .080″ x 12″ x R/L

- .090″ x 12″ x R/L

- .125″ x 12″ x R/L

- .187″ x 12″ x R/L

plate

- .250″ x 12″ x R/L

- .280″ x 24″ x R/L

- .375″ x 12″ x R/L

- .500″ x 12″ x R/L

- .625″ x 12″ x R/L

- .750″ x 12″ x R/L

- 1.0″ x 12″ x R/L

- 1.125″ x 12″ x R/L

- 1.187″ x 12″ x R/L

- 1.250″ x 12″ x R/L

- 1.375″ x 12″ x R/L

- 1.500″ x 12″ x R/L

- 1.750″ x 12″ x R/L

- 2.0″ x 12″ x R/L

wire

- .005″ Dia x 200 ft

- .010″ Dia x 200 ft

- .015″ Dia x 200 ft

- .020″ Dia x 200 ft

- .025″ Dia x 200 ft

- .030″ Dia x 200 ft

- .050″ Dia x 200 ft

- .060″ Dia x R/L Coil

- .080″ Dia x R/L Coil

- .090″ Dia x R/L Coil

- .125″ Dia x R/L Coil

rod

- .040″ Dia x R/L

- .050″ Dia x R/L

- .060″ Dia x R/L

- .062″ Dia x R/L

- .080″ Dia x R/L

- .090″ Dia x R/L

- .093″ Dia x R/L

- .125″ Dia x R/L

- .156″ Dia x R/L

- .187″ Dia x R/L

- .250″ Dia x R/L

- .312″ Dia x R/L

- .375″ Dia x R/L

- .437″ Dia x R/L

- .500″ Dia x R/L

- .625″ Dia x R/L

- .750″ Dia x R/L

- .875″ Dia x R/L

- 1.000″ Dia x R/L

- 1.125″ Dia x R/L

- 1.187″ Dia x R/L

- 1.250″ Dia x R/L

- 1.375″ Dia x R/L

- 1.500″ Dia x R/L

- 1.625″ Dia x R/L

- 1.750″ Dia x R/L

- 2.000″ Dia x R/L

- 2.125″ Dia x R/L

- 2.250″ Dia x R/L

- 2.375″ Dia x R/L

- 2.500″ Dia x R/L

What is Tungsten?

Tungsten is an element on the Periodic Table with an atomic number of 74. This gray, steel-like metal has the highest melting and boiling points (3422 °C & 5900 °C, respectively) of all the chemical elements, and it is nearly twice as dense as lead (19.3 g/cm3 vs. 11.3 g/cm3).

Compared to molybdenum, its thermal conductivity [164 W/(M・K) vs. 142 W/(M・K)] is slightly higher, and its thermal expansion coefficient (4.2×10-6 K-1 vs. 5.2×10-6 K-1) is slightly lower.

Tungsten’s high-temperature strength, combined with its good electrical resistivity, have made it a popular choice for other applications in addition to filaments.

First Uses of Tungsten

Tungsten’s first use was in incandescent lamp filaments. Even though incandescent lamps are being dislodged by more energy-efficient LED lamps, tungsten is still of great importance to the lighting industry because it offers exceptionally high strength at very high temperatures. In fact, it has the best high-temperature strength of the four common refractory metals: Molybdenum, Tantalum, Tungsten, and Niobium.

Some specialty incandescent lamps such as halogen lamps still use tungsten filaments, and high-intensity arc lamps employ tungsten electrodes.

Lamp filaments are not pure tungsten, but a “doped” alloy containing micron-sized potassium bubbles that stabilize the filament’s grain structure and produce a highly creep-resistant material. Arc lamp electrodes were previously made from tungsten doped with thoria (thorium oxide), but the thoria undergoes a nuclear decay process that produces radon. Concerns for radon exposure resulting from inhaling thoria particles have virtually eliminated the alloy’s use throughout the world.

Instead, alternative materials are now in use for such applications. Potassium-doped tungsten and tungsten doped with lanthanum oxide or a combination of lanthanum and zirconium oxides have replaced thoria-doped material.

While these alloys are not as effective at promoting easy arc formation and stable arcs in the lamps, they are far less of an environmental and health concern.

What is Tungsten Used For Today?

Tungsten is used for heating elements in vacuum furnaces that exceed the temperatures of molybdenum and tantalum as well as other heater applications.

Tungsten has also gained wide acceptance as an essential material in electrical contacts, glass-to-metal seals, supports, and electrodes.

The best-known applications for tungsten metal and its alloys are those requiring high-temperature strength and stability.

While the earliest tungsten product, incandescent lamp filaments, is a vanishing species around the world, tungsten still is an important source of material to make filaments for sophisticated devices unrelated to lighting.

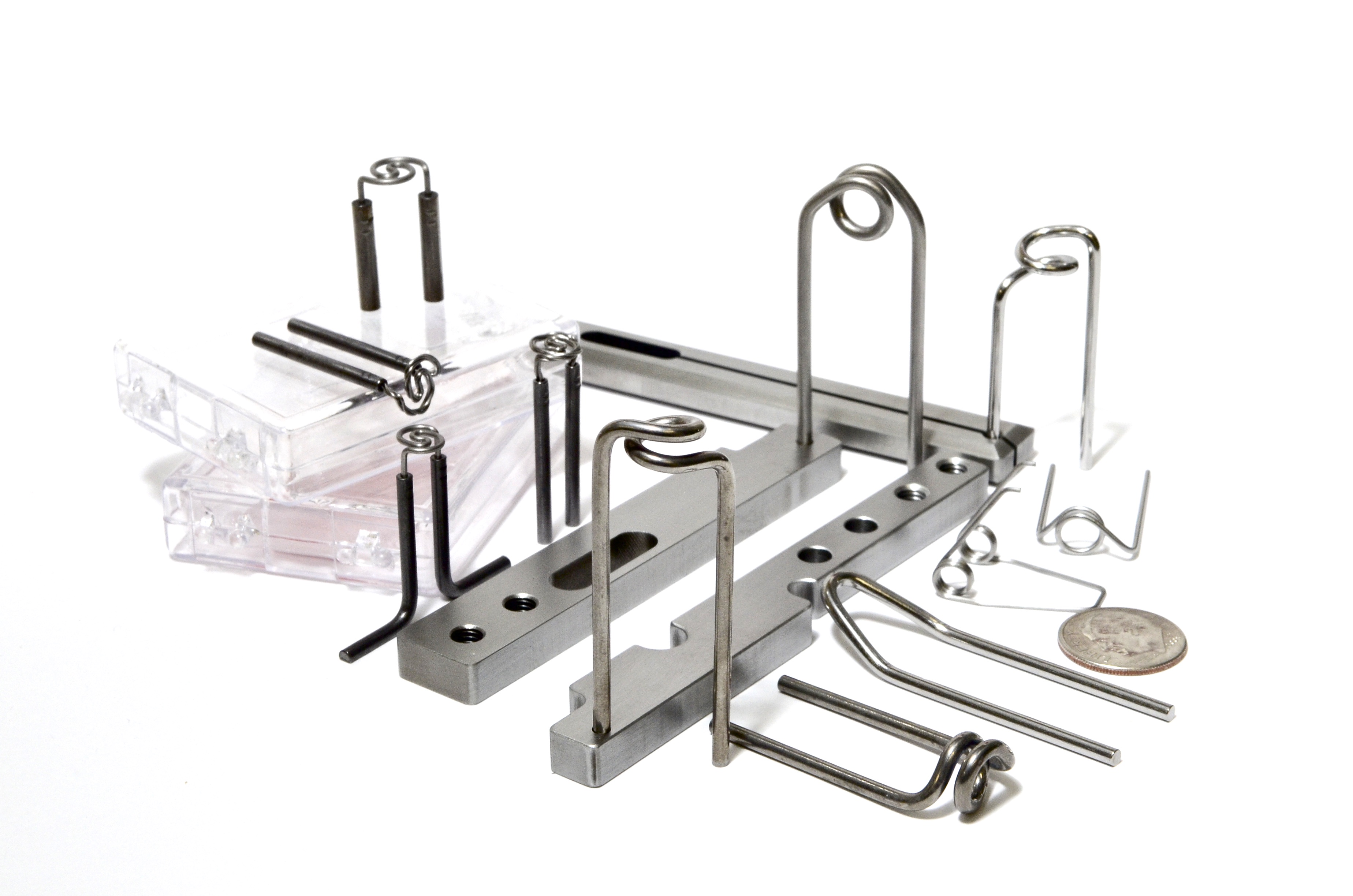

A host of different filament designs made from wire, coiled wire, rod, and sheet forms are the working heart of ion implanters, vacuum gauges, heating elements for semiconductor processing equipment, and analytical chemistry instrumentation.

Solid-state devices used in power electronics generate large amounts of heat that must be removed so that they can operate reliably and without degradation.

Tungsten-copper heat sinks are an excellent solution to this problem. The heat sinks are created by pressing tungsten powder, partially sintering pressed blanks to leave behind a controlled amount of interconnected porosity, and infiltrating molten copper into the porosity to form the finished blanks.

With the proper proportions of tungsten and copper, a copper-tungsten heat sink will closely match the device’s thermal expansion and conduct large amounts of heat away from the device.

Tungsten’s Melting Point

Tungsten’s high melting point (3422 °C & 5900 °C, respectively) makes it the material of choice for

- High-temperature vacuum-furnace components

- Heating elements

- Thermal shielding

- Supporting structures that must operate at temperatures above 2200 °C

Like molybdenum, tungsten forms a volatile oxide at high temperatures and must be protected by an inert gas, vacuum, or hydrogen.

High-temperature hydrogen furnaces also use tungsten heating elements because hydrogen protects it against oxidation by forming water vapor that flows out of the furnace.

Tungsten’s high-temperature strength and creep resistance are the keys to its use in furnace applications.

Tungsten finds its way into unusual furnace geometries. Hydrogen bell furnaces that operate at temperatures above 1500 °C sometimes use indirect induction to heat the furnace load. In such a design, a cylindrical susceptor is heated by induction and radiates heat to the workload it surrounds.

The susceptor is fabricated from a thick tungsten sheet so that it can sustain the necessary temperatures. Sintering furnaces for molybdenum and rhenium sometimes employ this design, which can attain temperatures exceeding 2100 °C. Induction-heated tungsten crucibles are also used as susceptors to produce single crystal forms of sapphire (aluminum oxide).

The tungsten crucible may hold the Al2O3 directly, or it may contain a molybdenum crucible holding sapphire starting material. Using sophisticated crystal-growing techniques, molten sapphire can be drawn from the crucible to form glass strips, or solidified under controlled conditions to produce large single-crystal “boules” from which individual parts are cut.

Applications of Tungsten

Applications for Tungsten include:

- Grocery-store scanner windows

- Guided missile domes

- Spectroscope windows

- Body armor

- X-ray equipment

- CAT scanners

Material bombarded by a high-energy electron beam emits X-rays having several unique wavelengths and a wider spectrum of “white radiation.” Tungsten’s white radiation spectrum is very broad and intense, so it is an ideal target material for medical X-ray machines.

Alloying tungsten with rhenium strengthens it and greatly improves its ductility, so tungsten-rhenium targets are an essential part of CAT scanning equipment.

CAT-scanners generate X-rays using a molybdenum disc rotating at about 10,000 RPM in a vacuum. A narrow track of W-Re alloy (tungsten-Rhenium alloy) embedded within the molybdenum alloy disc generates the scanner’s X-rays when struck by an electron beam produced by a tungsten filament.

The target experiences high cyclic heating and cooling rates during operation, and the tungsten-rhenium alloy is much more resistant to cracking and failure than pure tungsten would be. CAT scanners also employ thin tungsten foil components in the collimator structure that refines the X-ray beam after passing through the patient and before striking detectors that create the CAT image.

Tungsten and Radiation Effects

Resistance to radiation’s effects at high temperatures is a key reason for tungsten’s use in high-energy physics devices.

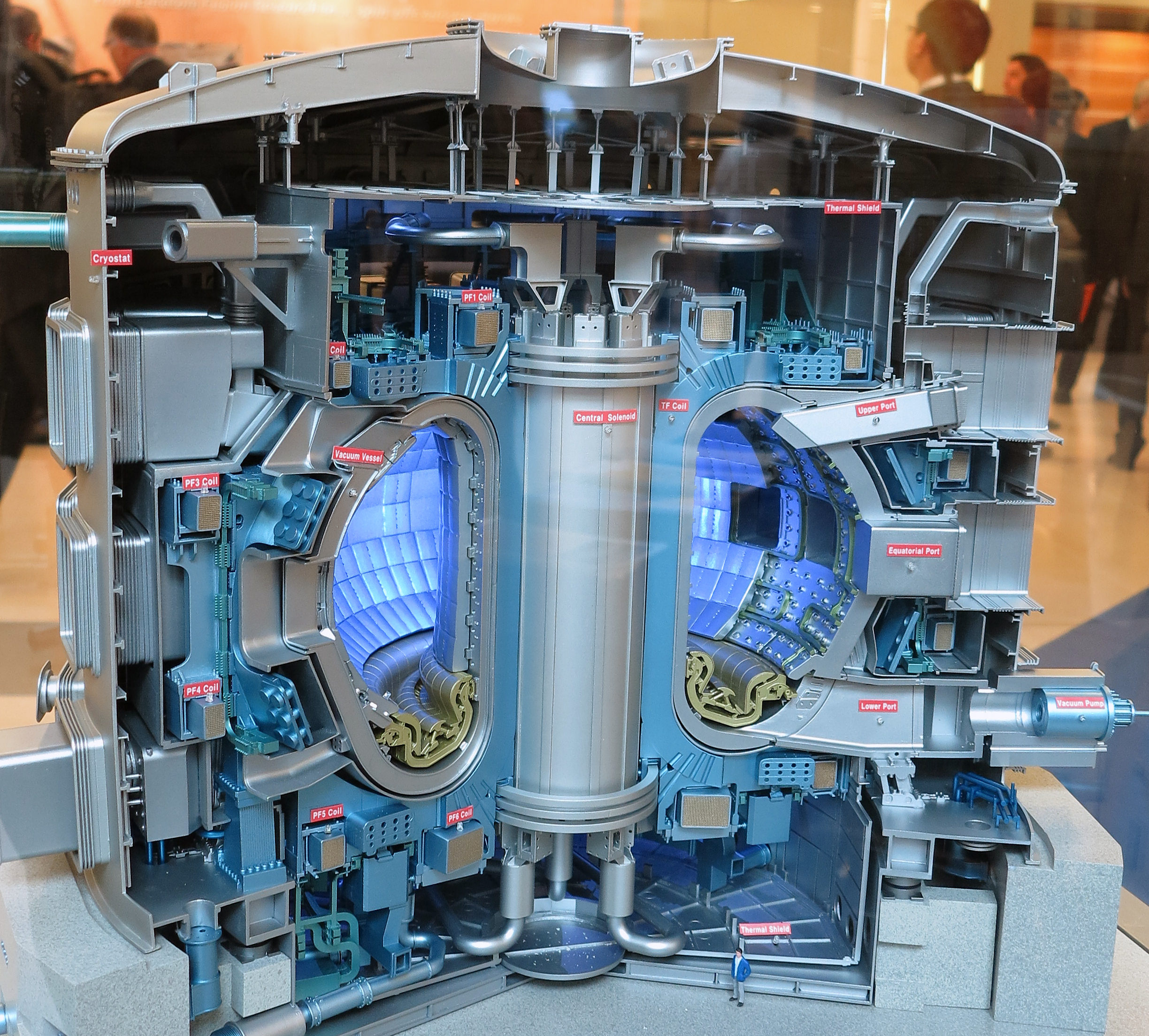

The International Thermonuclear Experimental Reactor (ITER) uses tungsten metal components in its divertor, the part of the reactor that extracts heat and ash produced by the fusion reaction.

This minimizes plasma contamination and protects the reactor walls from enormous thermal and neutron fluxes.

The divertor must sustain heat fluxes of 10 MW/m2 at steady-state operation and up to 20 MW/m2 under slow transient conditions. That means every square meter of the divertor must constantly transfer heat energy equivalent of 300 Formula 1 cars, each producing about 900 hp.

Tungsten is a contender for this application because of its high-temperature strength, good thermal conductivity, and low coefficient of thermal expansion.

Tungsten and Solid State Devices

Tungsten is important to solid-state device technology, as tools used to make thin films and as a thin-film material itself.

Tungsten-foil boats are filled with a material to be deposited on a substrate, and the boats are heated by the electric current under high vacuum to evaporate the material.

The evaporant then condenses on the substrate, producing a thin film. Tungsten sputtering targets manufactured from the plate are the source of tungsten for thin films on integrated circuits.

Sputtering creates a plasma of argon atoms above a tungsten target inside a vacuum chamber. A high-voltage field accelerates individual ions toward the tungsten target, where they dislodge tungsten atoms from the target and impel them toward the substrate to deposit and build up a thin film.

Sputtering targets require specialized rolling practices to maximize crystallographic uniformity so that film deposition is uniform on the substrate.

MATERIAL INFORMATION

DFARS-Compliant Tungsten Available

ASTM B760, ASTM F288 (ROD)

ASTM Certifications upon request

No cutting fee for custom lengths

Custom Sizes Available

Custom Stocking Plans Available

Technical Information

Tungsten is a greyish-white lustrous metal, which is a solid at room temperature. Tungsten has the highest melting point and lowest vapor pressure of all metals, and at temperatures over 1650°C has the highest tensile strength. It has excellent corrosion resistance and is attacked only slightly by most mineral acids.

Atomic Weight: 183.85

Density: 19.3 g/cc

Melting Point: 3695 K, 3422°C, 6192°F

Boiling Point: 6173 K, 5900°C, 10652°F

Coefficient of Thermal Expansion: (20°C) 4.4 x 10-6/°C

Electrical Resistivity: (20°C) 52.8 nO·m

Electrical Conductivity: (20 °C) 18.2 · 106 [1/(O·m)]

Specific Heat: (25°C): 0.13 J/g K.

Thermal Conductivity: 173 W/(m·K)

Modulus of Elasticity: (20°C) 405 [GPa]

Mass:

Density at 20° C gm/cc - 19.3

Density at 20° C lb/in 3 - 0.697

Thermal Properties:

Melting Point, °C - 3410

Boiling Point, °C - 5900

Linear Coefficient of Expansion per °C - 4.9 x 10-6

Thermal Conductivity at 20°C, cal/cm2/cm°C/sec. - 0.40

Specific Heat, cal/g/°C; 20°C - 0.032

Electrical Properties:

Conductivity, % IACS - 31%

Resistivity, microhms-cm; 20°C - 5.5

Temperature Coefficient of Resistivity per °C (0-100°C) - 0.0046

Mechanical Properties:

Tensile Strength at room temperature, psi - 100,000-500,000

Tensile Strength-500°C psi - 75,000-200,000

Tensile Strength-1000°C psi - 50,000-75,000

Young's Modulus of Elasticity; lb/in2:

Room Temperature - 59 x 106

500°C - 55 x 106

1000°C - 50 x 106

Spectral Emissivity:

(Wave Length approx. 0.65) - 0.37 (900°C)

Working Temperature: 1700°C

Recrystallizing Temp: 1200-1400°C

Stress Relieving Temp: 1100°C

Metallography:

Etchant - HF-NH; F sol

Polishing - Alumina - Rouge to finish

Need A Quote? Ready To Place An Order?