Pure Tungsten / Tungsten Nickel Iron Alloys / Tungsten Nickel Copper Alloys – Choosing the Right One for the Job –

Pure Tungsten (ASTM B760, ASTM F288)

Tungsten is an element on the Periodic Table with an atomic number of 74. This gray, steel-like metal has the highest melting and boiling points (3422 °C & 5900 °C, respectively) of all the chemical elements, and it is nearly twice as dense as lead (19.3 g/cm3 vs. 11.3 g/cm3). Compared to molybdenum, its thermal conductivity [164 W/(M・K) vs. 142 W/(M・K)] is slightly higher, and its thermal expansion coefficient (4.2×10-6 K-1 vs. 5.2×10-6 K-1) is slightly lower. Tungsten’s high-temperature strength, combined with its good electrical resistivity, have made it a popular choice for many high temperature applications. However, tungsten forms a volatile oxide at high temperatures and must be protected by an inert gas, vacuum or hydrogen. The best-known applications for pure tungsten metal and its alloys are those requiring high-temperature strength and stability.

Commercially-pure tungsten (99.95% min.) is the main element in the heavy metal alloying process, where other elements are added to form the tungsten heavy metal alloys. Tungsten’s contribution gives the resulting alloy exceptional strength and corrosion resistance as well as other useful properties.

Tungsten Heavy Metal Alloys (ASTM B777-15)

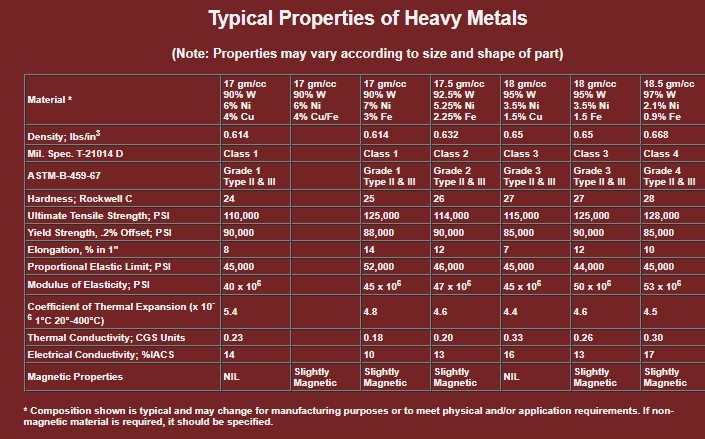

Tungsten heavy metal alloys are typically 90 – 97% tungsten with the balance of their composition being a combination of nickel and/or iron & copper metals which increase the ease of machining and the ductility of the alloy. Their composition is identified in the ASTM B777-15 specification, however, many people refer to the alloys by the trade names some manufacturers have given the alloys like “Densimet”, “Densalloy”, “Mallory” etc.

Choose tungsten heavy metal alloy (WHA) when your application requires a maximum concentrated weight in the smallest possible space.

A link to a printable pdf version of our tungsten alloys data sheet can be found on our website on the “Tungsten Alloys Stock” page: https://www.rembar.com/our-stock/tungsten-alloys/

Important Note: Tungsten heavy metal alloys are unsuitable for use in high temperature applications approaching or above 1450° C (2642° F) at which point pure tungsten should be considered.

We’ll look at the most popular types of tungsten alloys and the applications they are often used in.

Tungsten Nickel Iron Alloys

Tungsten nickel iron alloys provide a higher degree of strength, density & ductility over tungsten nickel copper alloys. With densities ranging from 16.85 to 18.85 g/cc, the tensile strengths of these nickel iron alloys are superior to most other alloys. These alloys are relatively easy to machine compared to pure tungsten, have excellent thermal conductivity and are able to withstand moderately high temperatures. Because iron makes these alloys magnetic, they cannot be used in any magnetism-sensitive equipment such as medical imaging equipment.

Tungsten Nickel Copper Alloys

The non-magnetic version of tungsten nickel iron alloys are tungsten nickel copper alloys.

Tungsten nickel copper alloys are less ductile and exhibit lower tensile strength than tungsten nickel iron alloys. However, their electrical conductivity is excellent and they provide a high level of thermal stability. Despite having a high mechanical strength, they are easy to conventionally precision-machine. The main reason tungsten nickel copper alloys are selected over nickel iron alloys is because they are non-magnetic. This attribute enables them to be used in a wide variety of applications where tungsten nickel iron alloys would cause magnetic interference.

Typical Applications of Tungsten Nickel Iron Alloys & Tungsten Nickel Copper Alloys

Medical Technology

- Thanks to their excellent capacity to absorb x-ray and gamma rays, tungsten nickel iron alloys are used in collimators and radiation shielding components in radiotherapy.

- As balances for optical precision instruments

- Used as radiation-shielding liners in transport of radioactive material

Aerospace

- Counter-balances in propellers, helicopter blades and rudders

- Avionic Systems

- Radar Systems

- Inertial damping weights

Automotive Industry

- Used as components in high-performance combustion engines due to their high mass & low volume.

- Crankshaft balance weights

- flywheel balance weights

- Drivetrain dampers & shock Absorbers

- Chassis Weights & Vibration dampening

Military

- Kinetic energy penetrators (ordnance)

Sporting Goods

- Darts

- Golf Club Heads

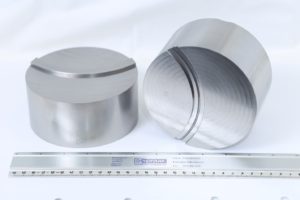

Rembar has 70 years experience machining tungsten alloys. We offer some of the shortest lead-times in the industry and are well equipped to custom fabricate parts in small or large quantities on short notice. Use the “FastQuote” form on our website or call us at 914-693-2620 and speak with one of our knowledgeable sales engineers.